Our gearing parts are manufactured on an area of approx. 2,500 m².

In some cases production takes place around the clock.

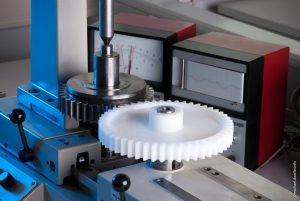

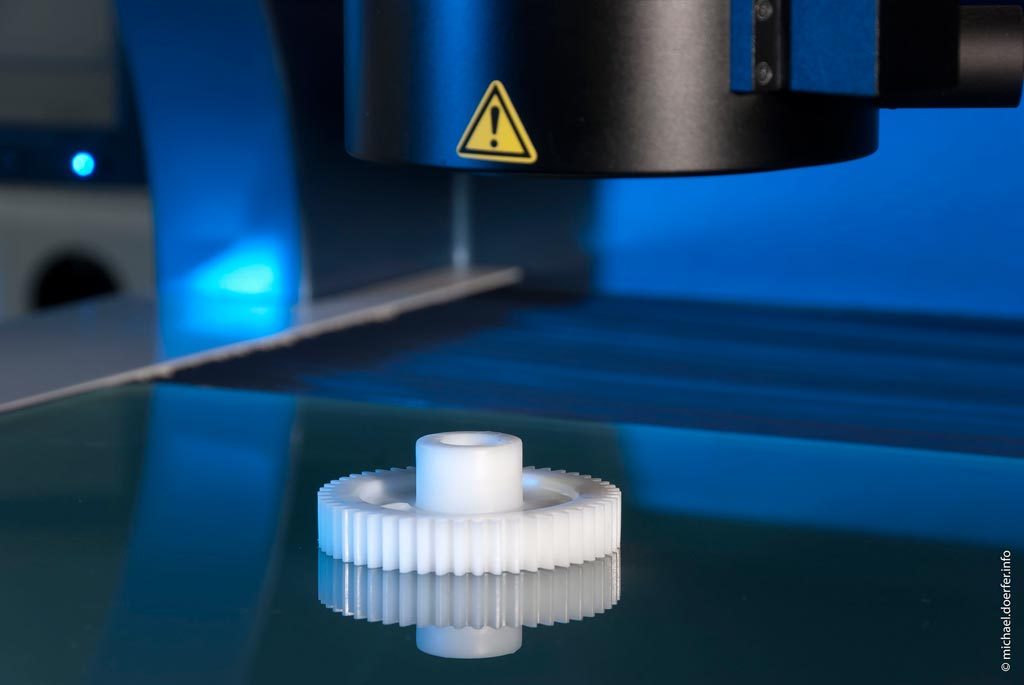

Product quality and delivery reliability are the major focus of our daily work. Directly after the injection moulding process the gearing parts are checked. This includes various visual and dimensional inspections.

It is our goal to gain appreciation from our customers through consulting engagement and product quality, which is then expressed in a long-standing partnership.

The introduction of the quality management system DIN EN ISO 9001:2015 is therefore an overarching management task. In close cooperation with all employees, the quality processes are illustrated, clearly defined and the respective responsibility is defined.