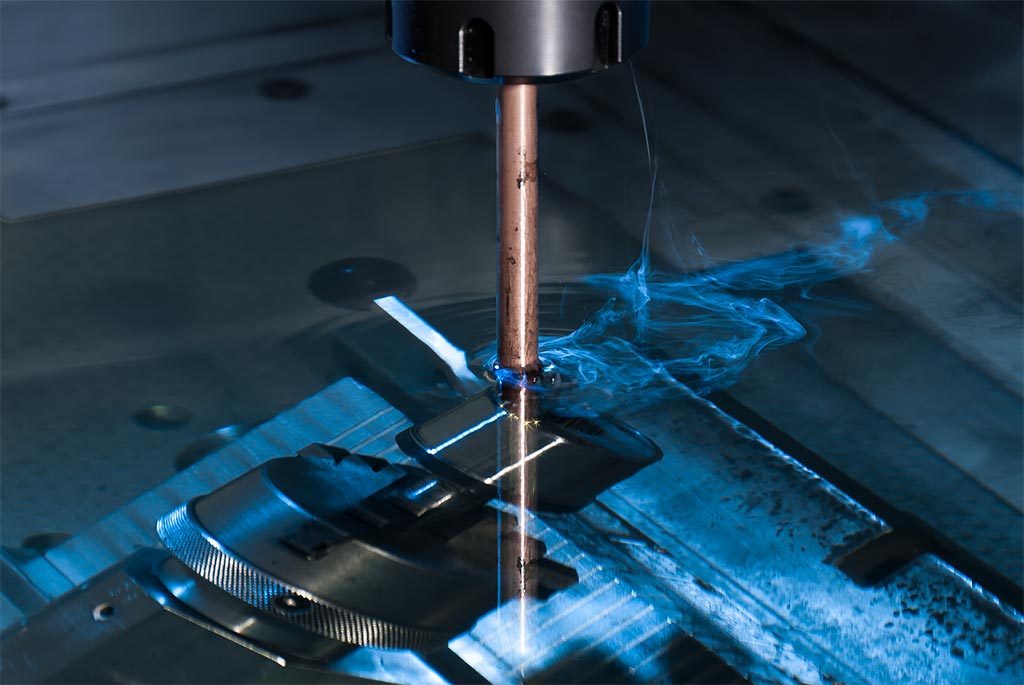

The tools are designed and manufactured in our tooling department, which is located at our Renningen site. On the injection moulding machines these moulds are then optimized up to readiness for series production.

With our tooling department in-house changes and repairs can be implemented quickly.

The tools of Zipperle Antriebstechnik GmbH are constructed in what we call „modular design“. This means that one tool can produce different gears by only replacing the inserts, while the mould itself remains clamped to the injection moulding machine. This procedure speeds up production processes and the manufacturing of new products does not require the construction of complete moulds, but only the necessary inserts. In this way, the customer is only charged with tool cost shares.

The tools as well as the interchangeable modular inserts are not for sale and remain property of Zipperle Antriebstechnik GmbH.